Physics Setup — Lesson 4

General

In the General tab, select "Axisymmetric Swirl" in the 2D space type. Keep the solver type as pressure-based to allow the premixed combustion model to be used.

Models

In the Models tab, double click on the Viscous option to change it from Viscous-Laminar to "k-ε (2 eqn)." Do not change any other parameters in the viscous dialogue box. Click "Ok" and close the dialogue box.

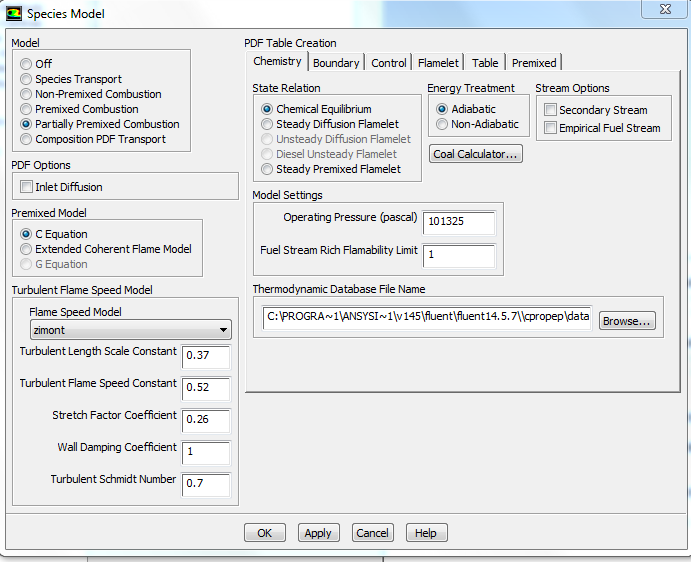

Now double click on the Species option to edit it, and change the model from Off to "Partially Premixed Combustion." In the Chemistry tab, change the Fuel Stream Rich Flammability Limit to 1. Changing this value means that Fluent will perform equilibrium calculations at all mixture fractions (1.0 being the largest possible fraction). If this was not the case, the composition would be computed based on mixing instead, for fractions above the specified limit.

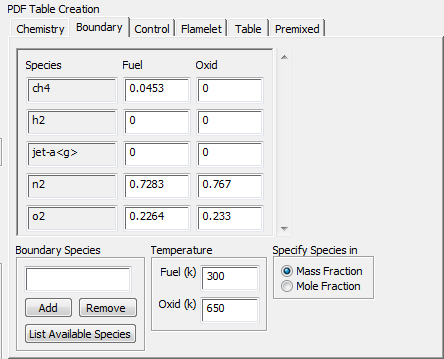

Click on the Boundary tab. Enter the values as shown in the following image. These values correspond to CH4 (methane) and air (nitrogen and oxygen) injected at a lean (less than 1.0) equivalence ratio of Φ = 0.8, representing the premixed fuel at T = 300 K. The equivalence ratio is defined as the ratio of two ratios: the fuel-to-oxidizer-ratio to the fuel-to-oxidizer-ratio-at-stoichiometric-conditions. In addition, oxidizer (air) will be injected as a co-flow outside of the fuel stream at 650 K. To add other species to the boundary, you would select the species you want and click "Add" under the Boundary Species options in this tab.

Ignore the Control and Flamelet tabs and select the Table tab. Click "Calculate PDF Table" to generate the pre-computed PDF table denoting mixture fractions that will handle the non-premixed combustion analysis. Investigate PDF table parameters and dependencies by clicking on "Display PDF Table," selecting desired options, and clicking "Display.

Back in the Premixed tab, click to edit the Laminar Flame Speed options, and note that various laminar flame speeds were calculated corresponding to various non-premixed mixture fractions. Click "Cancel" on these editing options to close the box, and click "Apply" and "OK" to close the Species dialogue box.

To write and save the PDF file that you just generated, go to File-Write-PDF in the menu at the top of the screen.

Materials

In the Materials section, select the material Mixture, and click "Create/Edit." Note how Fluent has pre-selected the material as a mixture and computes the density based on the PDF. Leave these pre-selected options. Click "Close."

Boundary Conditions

Because this is a turbulent model, in Solution Setup–Boundary Conditions, all turbulence parameters must be specified on the boundaries of the combustor.

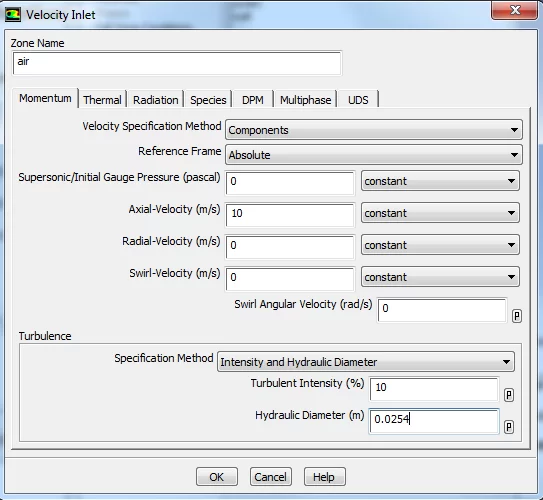

Click to edit the zone air (a velocity inlet). Change the velocity specification method to Components and set the axial velocity at 10 m/s. Change the Specification method to Intensity and Hydraulic diameter, and adjust the turbulence parameters as in the dialogue. Click "OK" once all the changes have been made.

Similarly, edit the air–fuel boundary to have velocity components, with 50 m/s axial velocity and 30 m/s swirl velocity. The turbulent intensity should be 10%, but the hydraulic diameter should again be 0.0254 m. Clicking the Species tab, change the mean mixture fraction to 1.0. This is because this stream will be taken as the fuel stream, whereas the previous air boundary did not need to be set beyond the default value of 0 for the oxidizer stream. Click "OK."

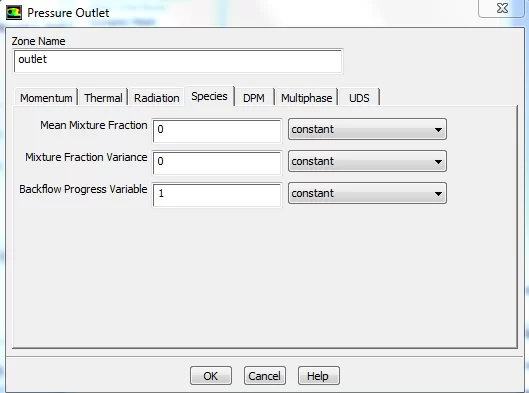

Edit the outlet boundary condition, which is a pressure outlet. Use 10% for Backflow Turbulent Intensity, and 0.13 m for the Backflow Hydraulic Diameter. Clicking the Species tab, change the Backflow Progress Variable to 1. This means that the boundary condition where the progress variable is 1.0 will only be applied in the case that there is backflow from this outlet.